|

|

When I first rebuilt my S14 to 2.5 L specifications I was interested in trying to get better mass-air flow through the engine, but I also wanted to retain good flow velocity (in order to achieve low RPM cylinder filling through inertia supercharging). Thus I chose to use a 2.3L Gr A header with a SuperSprint center resonator and stock muffler. The theory being that this would yield a lot of area under the torque and power curves. This theory was borne out at the dyno . But in the inevitable quest to tinker, I started to wonder if an Evo III header would not have been a better choice. The Evo III header has the same size primaries as the 2.3L Gr A header, but it has larger secondaries. Note that the Evo III header has the same p/n as the 2.5L Gr A header. This is explained in the summary of S14 headers. |

|

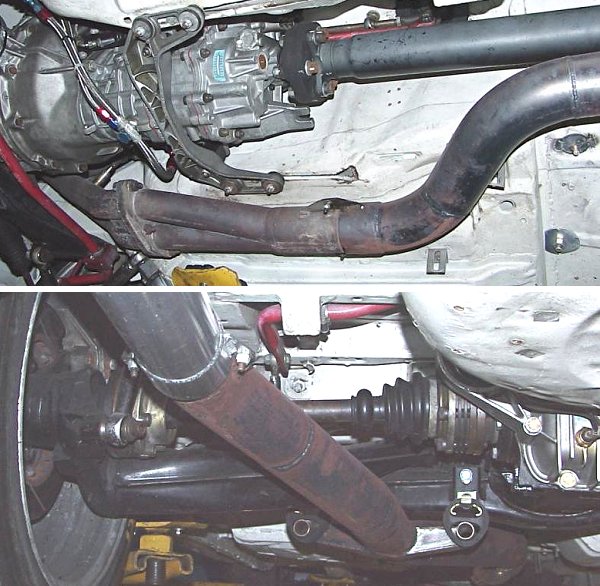

Because the Evo III header has larger secondaries than the stock 2.3L header, or the 2.3L Gr A header (55.5mm vs. 50.0mm and 48.0mm respectively), it is necessary to either acquire a complete Evo III exhaust, or build a custom exhaust. That way the larger 55.5mm secondaries of the Evo III header can flow straight into a larger Y-Pipe or X-Pipe without having a downward step in the tube ID. The stock dual exhaust has twin 45 mm tubes and would thus cause a significant downward step. This is very bad for flow and also introduces unplanned pressure reflections. I chose to manufacture a custom exhaust from stainless steel. I also chose to eliminate the factory style dual layout past the X-Pipe and instead implemented a Y-Pipe with a single 3.0" tube out to the back of the car. There is no theoretical advantage to a dual layout in terms of power. Once the exhaust hits the X-Pipe it is pretty much evenly distributed between both sides of the dual layout. Thus, as long as sufficient cross-sectional flow area is provided, it does not much matter if it's two small pipes, or one large pipe. My feeling is that the factory used a dual exhaust primarily in the interest of ground clearance. Two small pipes don't hang as far under the car as a single big tube. The packaging is easier with the dual layout. This is discussed in the X-Pipe theory section in Tech Articles. Evidence that the factory also found a single exhaust to be effective is provided by the following photos of an early style Gr A exhaust: |

|

|

Of course there are examples of factory E30 M3 race cars with dual exhaust systems. My feeling is that this was not done so much in the interest of power, but rather in an effort to comply with the racing regulations. Specifically DTM, which I always presumed had been a much more "open" body of rules than Gruppe A. In actuality, DTM was in many instances more restrictive than Gr A of the same time period. There may well have been rules in place during that time that required the factory DTM race cars to retain the street car exhaust layout (i.e. dual exhaust). In any case, notice the diameter of the single exhaust layout shown above. I would guess that the pipe diameter is on the order of 3.50" to 3.75" in diameter, which is simply huge! |

|

Page 2 » |

|

|