|

|

Here we see the Gr-A style control arm installed on my E30 M3. The geometry of the arm is quite important, and it is easy to mess things up if you do not know what you are doing. In the worst instance you can get binding in the rod ends when the control arm is adjusted away from its "as-built" geometry. The location of the three joints in 3D-space is also important, as this determines all of the relevant parameters of the front suspension such as roll center, camber curve, bump-steer, anti-dive, track, wheel base, caster, Ackerman etc... A couple of millimeters off here or there and everything changes. This is not a bad thing, if it is planned for. In fact I designed these arms to move the front wheels forward 10mm, which increases wheelbase, caster, Ackerman, and moves the weight distribution back. I also pushed the front wheels outwards by 10mm each, which increases track without using spacers (by 20mm), but also changes the Kingpin inclination, scrub radius and self-centering effect of the steering. When designing new suspension links, one must ensure that the rod ends and spherical bearings can accommodate the full range of expected suspension travel without binding up. This is especially important in bump, less so in droop. It is for this reason that I used a "high-misalignment" rod ends for the inner balljoint and lollipop mount. Note that the inner and outer balljoints of the control arms I've designed are still in single shear, just as with the factory control arms. This is not ideal from an engineering point of view, but it does make the arms a simple bolt-on installation. However, detailed design and top notch materials are called for to make it work safely. The BMW Motorsport cars sported a similar arrangement for the outer balljoint, but reworked the subframe, and rotated the inner rod end by 90° such that the inner joint was in double-shear. I do not think this was done for safety margin, as the outer ball joint carries more load than the inner under braking, and the same load under cornering. Rather, it appears that Motorsport managed to push the inner balljoint upwards into the subframe by 10-20mm in order to change the roll center. The factory race setup for the outer balljoint and tierod end is shown in the following photo. |

|

|

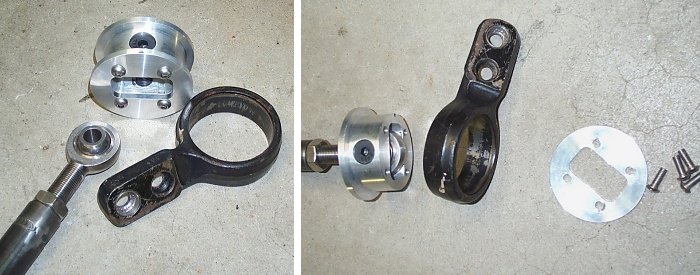

As mentioned before, only aerospace fasteners were used on this project. Tension bolts are used for the balljoints, not shear bolts (a shear bolt is used to attach the radius rod to the track rod though). And the tension bolts incorporate the proper radiused head with matching beveled washer as shown below. The nuts are either "Jet nuts" which are light and strong, but are really only a one-use kind of thing, or aerospace nylon locknuts, which can be re-used. This type of hardware is not cheap, but the strength and manufacturing tolerances are worth it. The inner balljoint bolts are $25 each, the outer balljoint bolts are $15 each. Sounds like a lot until you consider the consequences if one of these bolts fails. And it is not at all out of line to replace these bolts once per season (or more) on a heavily tracked car. A small price for peace of mind... |

|

|

The rear pickup for the radius rod was something that I contemplated for a while. Originally I planned to remanufacture the factory lollipop out of machined aluminum or steel to allow for moving the joint up and down to adjust anti-dive. This would still be the long term plan. But for the short term I simply made inserts for the factory forged steel lollipops. This works fine, although it is not adjustable. It also puts an unintended rearward load on the lollipop which it was not strictly designed for. I made an engineering call on this one and am convinced that the factory lollipops are quite strong enough to contend with the applied loads (I have encountered no problems with this setup). Nonetheless it is the plan to add bracing from the lollipop to the subframe, both to help with this rearward load and to triangulate the subframe and stiffen up the chassis. This mod is in progress. |

|