|

| |||

We have asked the question - can

a longer rod be used to decrease piston acceleration and thereby allow the bottom end

of an engine to reliably sustain higher rpms?

We have asked the question - can

a longer rod be used to decrease piston acceleration and thereby allow the bottom end

of an engine to reliably sustain higher rpms?

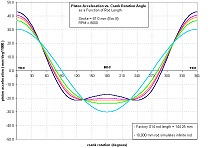

The following link shows how the piston acceleration curve changes as the rod length is modified (again for an Evo III stroke of 87 mm and a constant engine speed of 8000 rpm): | |||

| Click here for piston acceleration curves as a function of rod length... | |||

|

This series of curves shows that a longer rod reduces the maximum piston acceleration. An infinitely long rod (approximated here as one that is 10 meters long) will reduce the peak acceleration by 23% (relative to a factory Evo III configuration). But that's as low as the acceleration can be made to go with an 87 mm stroke at 8000 rpm. As the rod gets shorter, on the other hand, the max. piston acceleration is increased, but only at TDC. At BDC, the piston acceleration is actually reduced by a shorter rod (at least intially). The piston acceleration curve also begins to form a characteristic "double-hump" shape. If one were to keep making the rod shorter until it was only as long as the crank arm radius (a shorter rod than this would prevent the crank from completing a rotation), then the piston essentially would come to a "sudden" stop at 90° ATDC and it would "suddenly" start moving upwards again at 90° BTDC. These sudden stops and starts lead to infinite acceleration at 90° after and before TDC, and this is what the double-hump is starting to show. Of course this is all pure theory, as in practice the piston and rod consume space which makes the previous example impossible to achieve. But looking at the theoretical limits of an engineering problem is always instructive. | |||

|

Now a seasoned engine builder might consider trying to package a longer rod into the existing cylinder block. The reasons for wanting to try this can vary, and one of them might be to try and reduce the max. piston acceleration in an attempt to allow the bottom end to safely maintain higher rpms. So let's say we want to try this on an S14 engine with an Evo III crank. If we work real hard at squeezing the ring pack together, possibly pushing the wrist pin up past the oil scraper ring, and we reduce the OD of the wrist pin to a minimum, then we might just be able to wedge in a 1 cm longer rod. Having accomplished this we could be quite proud of ourselves in having built an S14 capable of higher rpms due to the reduced max. piston acceleration. But how much has the max. piston acceleration really been brought down? This is easy to determine with our spreadsheet, as shown in the following link: | |||

| Click here for max. piston acceleration with a 1 cm longer rod... | |||

|

The curve is blown up to concentrate on the region near TDC (0° crank rotation) in order to better see the change in max. piston acceleration. And the answer is somewhat discouraging. The acceleration is only reduced by roughly 1.5% after all our efforts to lengthen the rod. Now this result should not be considered inconsequential. For example, if the previous redline limit for bottom end integrity had been, say 8200 rpm, then it is now raised to 8323 rpm. That's something you can hang your hat on. But depending on your application, it may or may not be worth the effort required. Remember too that, as previously mentioned, there are additional reasons why one might want to try a different rod ratio. | |||

|

The piston kinematics spreadsheet is fun to play around with. Should the reader desire to perform further experimentation, the spreadsheet can be downloaded via the following link: | |||

| Click here to download the piston kinematics Excel spreadsheet... | |||

|

| |||

|

|