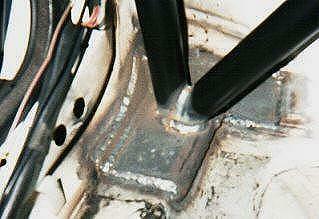

Here is the

same baseplate as above, but with the diagonal fit into place (hence the

extra tube). An important fact to remember when welding in a roll

bar or cage is that all of the welded areas must be cleaned and painted

after welding. Otherwise rust will set in. This is especially

true on the bottom of the car. The heat from the welding process

burns off the undercoating and this must be scraped off and then painted

with a good rust-stopping paint (Wurth makes a good brush on type).

It's an ugly, hideous job but it has to be done 8^(

Here is the

same baseplate as above, but with the diagonal fit into place (hence the

extra tube). An important fact to remember when welding in a roll

bar or cage is that all of the welded areas must be cleaned and painted

after welding. Otherwise rust will set in. This is especially

true on the bottom of the car. The heat from the welding process

burns off the undercoating and this must be scraped off and then painted

with a good rust-stopping paint (Wurth makes a good brush on type).

It's an ugly, hideous job but it has to be done 8^(

The main hoop was put in first so that Sean could weld all the way around the junction to the baseplate. If the diagonal had been put in at the same time then this would not have been possible. |

Now we see

the entire roll bar. I chose not to extend the horizontal harness

bar all the way across to the passenger side. This way I can still

use the back seat for carrying tires etc. I wanted to keep the entire

rear interior intact - just as a matter of principal. I had my fill

of a stripped out tin can in my Rabbit days 8^)

Now we see

the entire roll bar. I chose not to extend the horizontal harness

bar all the way across to the passenger side. This way I can still

use the back seat for carrying tires etc. I wanted to keep the entire

rear interior intact - just as a matter of principal. I had my fill

of a stripped out tin can in my Rabbit days 8^)

Note that the rear pop-out windows are removed. This was invaluable during construction of the roll-bar. And is was also a good way to put the rear seat-back in after completion of the project! |

On the far side of the car (above) you will see that we broke one of the cardinal rules of cage building - namely that all tubes should come together at junctions. The rear down-bars really should have met the main hoop a bit higher up and the diagonal should have gone farther over so that they would have come together. But we had to make some compromises in order to be able to keep all of the interior trim. The cage is made of 1.50" x 0.120" DOM tubing, as required by the SCCA GCR (General Competition Rules). I do not plan on doing any "fender banging" with this car (any time soon), but I figured the SCCA guidelines would ensure that my roll bar was adequate for the task at hand. In time I will tie the roll bar into the hard-points for the shoulder belts on the B-pillars (rumor has it that there are identical hardpoints underneath the plastic trim on the A-Pillars - probably a hold-over from the factory Touring Car days). This should really help stiffen up the chassis. But even with the roll bar as it is, I noticed an impressive increase in torsional rigidity (such as when driving sideways up a driveway). This helps the handling of the car as the two ends of the chassis are not fighting each other as much. By far the greatest chassis rigidity in the modern racing world can be found in European Super Touring cars (greater even than F1). These guys have taken the art of cage building to a whole new level. NASCAR cages may look impressive but they have so much flex in their cars that they actually account for it as part of their suspension tuning! |