It is quite common when rebuilding an engine to "overbore" the cylinders. This way a larger

diameter piston can be fitted which increases the swept area of the pistons and therefore leads

to an increase in displacement. The larger displacement consequently provides more torque and power.

It is quite common when rebuilding an engine to "overbore" the cylinders. This way a larger

diameter piston can be fitted which increases the swept area of the pistons and therefore leads

to an increase in displacement. The larger displacement consequently provides more torque and power.

Owners of the S14 powerplant are fortunate. A factory solution to bigger displacement exists in the form of the BMW Motorsport Evolution III engine. This engine was a special homologation during the last year of production for the e30 m3 and displaces 2.5 liters as opposed to the standard 2.3 liters. The increase in size came about through an increase in the stroke from 84 mm to 87 mm and an increase in cylinder bore from 93.4 mm to 95 mm. Thus when rebuilding a 2.3 liter S14 engine it is fairly common to increase the displacement to Evo III specs. Increasing the stroke is easy as the 2.5 liter crank bolts right in and is fairly affordable. However, increasing the bore poses a quandary. |

|

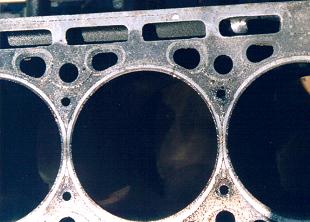

The factory Evo III 2.5 liter engines had a unique block part number. It is commonly believed that this E3 block has a thicker casting in order to accommodate the larger bore. Prevailing wisdom says that the standard 2.3 L block might be too thin to safely accept a 95 mm bore. I am unable to verify whether the E3 block really does have a thicker casting. I have seen a brand new E3 block. They appear to be available in limited quantities from the factory for about $1700 with pistons. I had the opportunity to inspect an E3 block at Long Beach BMW. Visually it was identical to a standard 2.3L block save for a machined pad at the base of each cylinder to accept an under-piston oil squirter. Certainly the block thickness between the "Siamese'd" cylinder bores is the same on both blocks as they have the same cylinder spacing (otherwise they would not be able to share cranks). This does not rule out the possibility that the rest of the cylinder wall might be thicker. But the question is: even if the standard 2.3L cylinder walls are a bit thinner than the 2.5L block, what is the maximum bore that the 2.3 block will safely accept? |

|

To answer this question conclusively it is necessary to have the cylinder block "sonic tested". Sonic testing is discussed on the next page » |