|

|

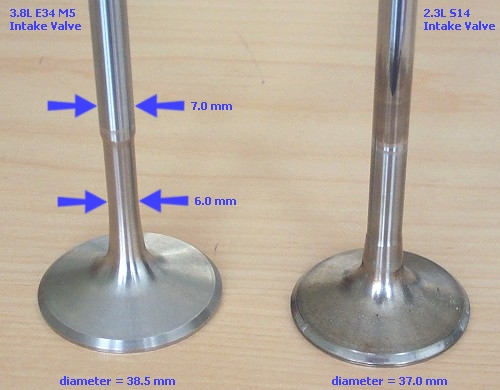

The photo shows an intake valve from the Euro only 3.8L E34 M5. A standard 2.3L E30 M3 intake valve is shown

on the right for comparison. As is commonly known, the E28 M5 and E34 M5 engines shared many design

features with the S14 engine in the E30 M3. The cylinder heads, specifically, are quite similar.

In this case it turns out that the intake valves from the 3.8L E34 M5 are a drop in

replacement for the S14 Evolution 3 cylinder head. The intake valves measure 38.5 mm in diameter,

just as with the Evo 3.

The photo shows an intake valve from the Euro only 3.8L E34 M5. A standard 2.3L E30 M3 intake valve is shown

on the right for comparison. As is commonly known, the E28 M5 and E34 M5 engines shared many design

features with the S14 engine in the E30 M3. The cylinder heads, specifically, are quite similar.

In this case it turns out that the intake valves from the 3.8L E34 M5 are a drop in

replacement for the S14 Evolution 3 cylinder head. The intake valves measure 38.5 mm in diameter,

just as with the Evo 3.

Rumor has it that combining the intake valves from the 3.8L E34 M5 with the Evo 3 cylinder head has been a "hot tuning tip" in Germany for some years. I was not really sure why - I had only heard that the valves from the E34 M5 were somehow "better". Once I got my hands on some 3.8L E34 M5 valves I could easily see at least one obvious improvement. The intake valve stem has a variable diameter. |

|

The nominal valve stem diameter for an S14 head is 7 mm. On the S14 valves, the 7 mm diameter is maintained all the way down the stem. However, on the 3.8L E34 M5 intake valve, the stem necks down to 6 mm over that portion of the stem which sits inside the intake port. This reduces the flow obstruction through the ports. Going to a smaller valve stem diameter is not a new trick, but usually the entire valve stem is reduced in size. This necessitates new valve guides and seals, and also weakens the valve somewhat. But here is a factory solution which drops right into an Evo 3 head (or a ported 2.3L S14 head) using the standard 7 mm guides and seals. The 3.8L E34 M5 valve is also probably somewhat stronger than a pure 6 mm valve stem, although some strength is obviously lost in the thinner section when compared to a pure 7 mm valve stem. Also, while the variable stem diameter is a nice way to reduce port flow obstruction without changing too much else, it will not be as light as a valve with an end-to-end 6 mm stem. And once you start getting above 8000 rpm, valvetrain mass reduction becomes important. These are all factors to keep in mind. |

|

|

So what's the bottom line here? Well, if you are planning on building up an Evo 3 cylinder head, or more likely, modifying a standard cylinder head to include larger intake valves, then the 3.8L Euro E34 M5 valves might be worth considering. They are a factory solution to smaller 6 mm intake valve stems. But they don't come cheap. Schrick valves will be cheaper, and arguably just as effective. Schrick valves can also be had "swirl polished", and the possible effects of this trait on combustion efficiency (and hence power output) should not be under-estimated. Still, it's always nice to have choices right? |

Why all this effort to reduce the stem diameter on the intake valve, and not the exhaust valve?

Well, remember that the exhaust gases start to exit the cylinder during the "blow-down" phase.

In other words, during that time when the combustion gases are still expanding. The exhaust valve

on a performance cam will open well before bottom-dead-center (BDC). Hence the expansion of the

combustion gases is used to start pushing them out past the exhaust valve (seems wasteful,

but it works out better that way in the overall picture). Once that is done the

piston starts to move up and finish the job of pushing the exhaust gases down the header.

So in general there is a higher pressure differential

available to "push" exhaust gases out past the exhaust valve, when compared to the pressure differential that is available

to "suck" the intake charge past the intake valve. For this reason it is often more effective to

work on minimizing the intake path flow restriction, since that is usually the limiting case in

getting air and fuel in and out of the cylinder.

Why all this effort to reduce the stem diameter on the intake valve, and not the exhaust valve?

Well, remember that the exhaust gases start to exit the cylinder during the "blow-down" phase.

In other words, during that time when the combustion gases are still expanding. The exhaust valve

on a performance cam will open well before bottom-dead-center (BDC). Hence the expansion of the

combustion gases is used to start pushing them out past the exhaust valve (seems wasteful,

but it works out better that way in the overall picture). Once that is done the

piston starts to move up and finish the job of pushing the exhaust gases down the header.

So in general there is a higher pressure differential

available to "push" exhaust gases out past the exhaust valve, when compared to the pressure differential that is available

to "suck" the intake charge past the intake valve. For this reason it is often more effective to

work on minimizing the intake path flow restriction, since that is usually the limiting case in

getting air and fuel in and out of the cylinder.

The shape of the valve is also very much governed by the direction of the flow of air around it. This direction is obviously completely reversed for an exhaust valve relative to an intake valve. Lastly, one will note that the head of the exhaust valve is quite robust when compared to the intake valve. This is to some extent due to the fact that the exhaust valve gets much hotter, and it must withstand this heat until it can conduct it to the cylinder head through the valve seats during that time when the valve is closed. Thus more material means more thermal mass, and hence a greater capacity to absorb heat until it can cool. Also, the extra material provides improved mechanical strength, which is necessary because the strength of metal is reduced at elevated temperatures. All of these factors help explain why an intake valve tends to look a lot different than an exhaust valve. |