|

Double-Piston Design w/ Enclosed Spring: Whereas the standard S14 timing chain tensioner is a single piston design, the newer S50/S52 tensioner is a double-piston unit. This can be seen in the photo above. What constitutes the first piston is obvious. But note that the portion of the first piston that sticks out to the right of the orange line is actually a second piston, which resides inside the first. Furthermore, this second (smaller) piston also has a strong spring behind it. However, since the second piston is held inside the larger first piston via a circlip, the spring says compressed even when the unit is removed from the car. For a time I believed that it was the double piston design that allowed this tensioner to produce a greater oil pressure force on the tensioning rail. This greater force I presumed was responsible for the reduced timing chain rattle. However, it was pointed out to me by Jon Thelen (an early proponent of this mod) that my analysis was incorrect. In actuality, the spring in the S50/S52 tensioner is probably largely responsible for it's improved performance over the stock S14 tensioner. This is explained below:

Development of Forces:

For the record, the diameter of the stock S14 timing chain tensioner piston is 19.5 mm.

This yields a cross-sectional area of 299 mm˛ (0.46 in˛).

With the S50/S52 tensioner, the diameter of pistons #1 and #2 are 18.0 mm and 15.0 mm respectively.

This gives cross-sectional areas of 255 mm˛ and 177 mm˛ (0.39 in˛ and 0.27 in˛).

Now one way that the timing chain tensioner develops force against the tensioning rail is by converting oil

pressure to a force. It cannot change the oil pressure that is delivered to it. That pressure

is dictated by parameters within the engine (and is rpm dependent).

Force = Pressure x Area

Note that the schematic above depicts the tensioner in what I will call its "extended"

position. However, imagine what happens when the oil pressure is zero. At this time all the forces

in red (oil pressure forces) will be zero. The only force against the tensioning rail will be

created by the spring (the blue arrows). Piston #1 will be completely pushed into cylinder #1 and

the tensioner will be in its "retracted" position. It is not until the oil pressure is high enough that

F1 = F2 + Fs that piston #1 will begin to move outwards. This happens at what I term the "break point"

and as oil pressure rises beyond this point the spring forces completely cancel and the force on the

tensioning rail is entirely created by oil pressure.

|

The development of the force against the timing chain tensioning rail as oil pressure rises

is shown in the graph to the left. Note that this is not to scale and is qualitative, not

quantitative. I have no knowledge of the spring rate or its degree of compression in the

static position, so it is not possible to generate real numbers. But this is most likely

a good representation of what happens.

The development of the force against the timing chain tensioning rail as oil pressure rises

is shown in the graph to the left. Note that this is not to scale and is qualitative, not

quantitative. I have no knowledge of the spring rate or its degree of compression in the

static position, so it is not possible to generate real numbers. But this is most likely

a good representation of what happens.

The spring force is shown as a horizontal line which implies that the spring force on the rail is constant and independent of oil pressure. To first order this is true, as the relative compression of the spring past the break point is presumable negligible relative to how far it has already been compressed inside the tensioner (and held in place via the circlip). Past the break point the spring does have to compress in order to maintain a force balance, but things are complicated enough already ;-) |

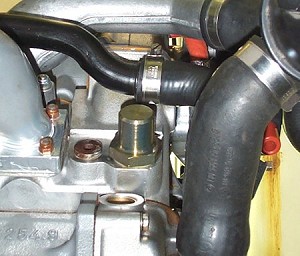

Installation of the S50/S52 timing chain tensioner is a "slam dunk". It simply screws right into the

cylinder head. And since you don't have to compress the spring at the same time that you are trying

to line up the threads to engage the tensioner, things are a lot easier. There is no provision

to prelube the S50/S52 tensioner, but prelubing is not required (I never did it with the old S14

tensioner either).

Installation of the S50/S52 timing chain tensioner is a "slam dunk". It simply screws right into the

cylinder head. And since you don't have to compress the spring at the same time that you are trying

to line up the threads to engage the tensioner, things are a lot easier. There is no provision

to prelube the S50/S52 tensioner, but prelubing is not required (I never did it with the old S14

tensioner either).

Note that the "slam dunk" comment might not apply if your tensioner arrives

in the "disassembled" condition. Based on user comments, the tensioner is often obtained from

the dealer with the second piston separated from the intermediate cylinder (see picture link below).

Presumably a small

whack of the tensioner on a hard object during shipping and handling can pop the circlip loose

so that the second piston is pushed out by the spring. The solution is to patiently push the

tensioner together on the work bench and then use your third and fourth hands (or a helper

So in conclusion, my current theory is that the reduction in timing chain rattle caused by the

S50/S52 timing chain tensioner is due to the addition of a much stronger spring. As we have seen above,

when oil pressure is low, most of the force on the tensioning rail is produced solely by the

spring. So the only real way to reduce rattle on startup, when oil pressure is low, is by having

a stronger spring. Quite possibly BMW chose to enclose the spring within the tensioner, as otherwise

it would be very difficult to install. Furthermore, the double-piston design of the S50/S52

tensioner produces a "rising rate", so that additional force can be applied to the timing chain tensioner

under high RPM conditions, when it is needed most.

|

|

Photo comparison of the two timing chain tensioners... |

|

Photo of a partially disassembled S50/S52 tensioner... |

|

Exploded view of 081 tensioner #1 |

|

Exploded view of 081 tensioner #2 |

|

Exploded view of 081 tensioner #3 |

|

Exploded view of 081 tensioner #4 |